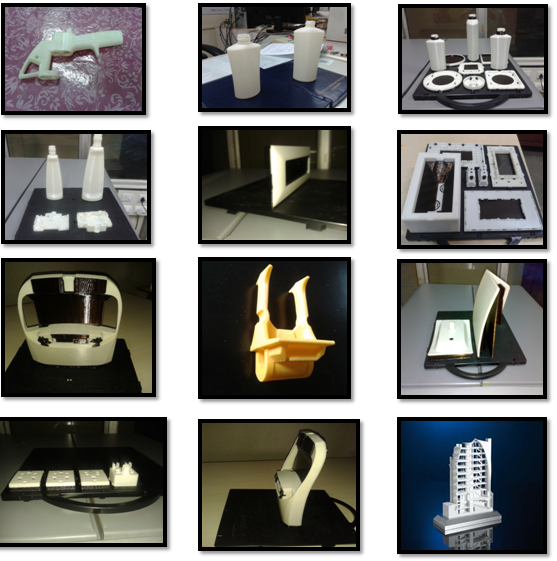

Rapid Prototyping in Plastic

FDM :

FDM is the ideal solution for:

- Prototypes for functional testing; you can install and run the parts in your production intent material for the best possible proof that your design really works.

- Prototypes for form ad fit testing

- Prototypes directly constructed in production materials

- Quality parts with a high stability

- Durable single piece parts up to 300 x 250 x 250 mm

- Low volume production

- FDM is the ideal technology to build large, flat parts

Some good reasons to choose FDM :

- High accuracy

- Functional parts

- Water –soluble support structure

- Production materials

- Durable parts with great stability

- Short throughput times thanks to large capacity

Machine Specification :

- Abbreviation: FDM (Fused Deposition Modelling)

- Material Type: Solid

- Material: Thermoplastics such as ABS

- Max Part Size: 300mm x 250mm x 250mm

- Min Layer Thickness: .20mm

- Accuracy: ± .20mm

- Build Speed: Fast

SLS (Upcoming) :

Contact:

Mr. Yogesh Adsul

Junior Technical Assistant(J.T.A)

E-mail : toolroom@idemi.org

Phone No : 022-24050301/02/03/04 ext 254

Mobile No: 9869507626